| Show list | Next article |

Grid-Tape

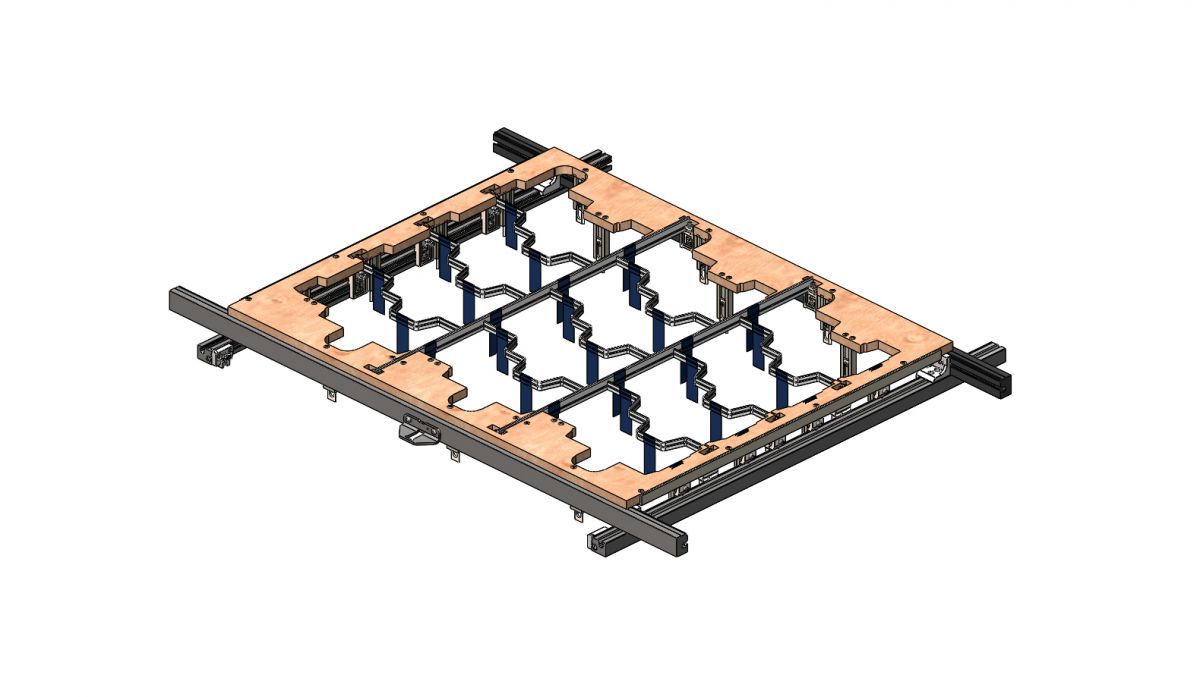

Grid-Tape has been developed in cooperation with European die makers in order to eliminate the use of time consuming self-adhesive ribbons on lower blanking tools. Grid-Tape realises significant time savings (up to 90%!). Grid-Tape is very easy to apply without the need of any calliper or ruler.

Before Grid-tape was introduced, die makers used costly plastic tape. The tape and steel shims had to be cut exactly between 62 and 55 mm. (2,44 and 2,16 inch). Next one had to tape the steel shim in between the plastic tape and over the grid material. This was very hard to do because of the high levels of precision that are needed in this process.

Save precious time with Grid-Tape!

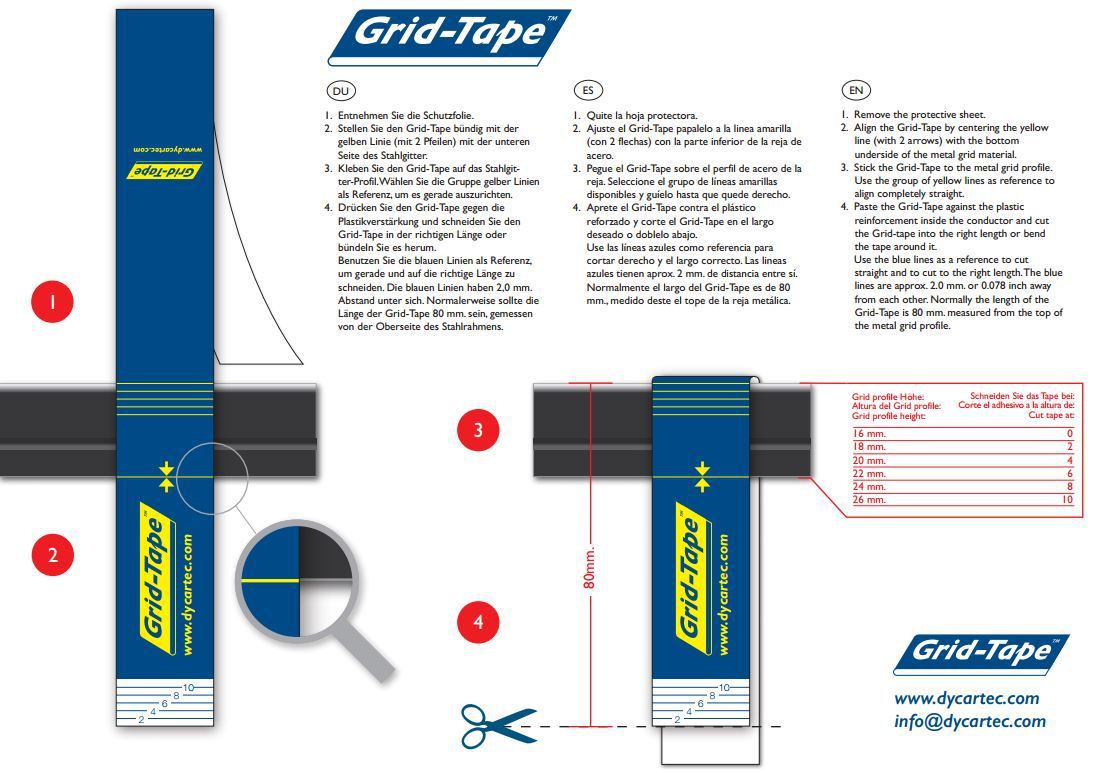

1. Time savings up to 90% as a result of fast application that allows for very accurate positioning within 5 seconds.

2. Grid-Tape forms one undivided whole. No need for separate - expensive - plastic tape and shim band.

3. Stable conduction during separation / blanking as a result of high grade plastic inside the conductor.

4. Protective sheet is 1 mm bigger than Grid-Tape on all sides, making it easy to remove.

5. Very hard wearing material, almost impossible to tear.

6. Powerful adhesive, especially designed for bonding on greasy steel and plastic.

7. Register lines for quick and accurate aligning.

8. Register lines aligns the Grid-Tape straight.

9. Cutting register ensures quick and accurate cutting of the Grid-Tape.

10. Grid-Tape contains no metals (not allowed in dies for food industry)

11. Compatible with BSI Blanking Systems, Angle lock and Quickset system.

12. Suitable for al metal grid profiles from 16 x 2 mm. tot 25 x 6 mm. (0.98 x 7.24 inch)

A box of Grid-Tape contains 200 tapes, ready to save time!

Customer testimonials

Martin Rönngard

CEO/Owner Stållinjestans AB Laserform, Sweden – Die Maker

As one of the first Die Makers in Europe we started to use Grid-Tape. We save a tremendous amount of time every Grid-Tape we position in a lower blanking tool compared to how it was done with cello tape together with a piece of metal shim. The accuracy of positioning is unmatched, since accuracy is key in nowadays modern die making, Grid-Tape contributes to the high Standards we produce for our customers every single day

Edwin Jansen,

Production Manager die cutters Remmert Dekker b.v., Netherlands - Cardboard Converter

We run 2x Bobst Sprintera 106PER almost always full speed (12.000 s.p.h.) Since Grid-Tape was introduced we never had to abort a production run in order to replace Grid-Tape. In the earlier days our Die Maker glued a kind of household tape with a metal shim inside on our lower blanking tools. This was a nightmare to replace after a machine stop. With the tooling in the machine replacing this household tape was a timewasting challenge. Not any longer, thanks to Grid-Tape.

Jeroen van Heerde,

CEO/Owner Diefac Stansvormen b.v. & Beekman Stansvormen b.v., Netherlands – Die Maker

Since its introduction we use Grid-Tape on almost all of our lower blanking tools. Delivery times are getting shorter and shorter every year. Efficiency and being in control over your processes are key in getting the orders on time to your customers. The time my people spend on gluing conventional tapes on our blanking tools was against our believe in running an efficient workflow. Now they can focus on more important tasks in order to get our high end tooling in time to our customers. Starting to use Grid-Tape was a no brainer for us.

Agent for North America:

| Blanking Systems Inc. | Phone: 1-262-377-3591 | Russ Kempka, Technical Specialist |

| 440 9th Avenue | Fax: 1-262-377-2005 | russ.kempka@blankingsystems.com |

| Grafton WI 53024, USA | www.blankingsystems.com |

Agent for South America:

Agent for South America:

| Appel Group | Tel: +49-7021-978 424 | Francisco Appel, Technical Specialist |

| Marderweg 15 | Fax: +49-7021-978 426 | Francisco.Appel@appel-diecutting.com |

| D-73230 Kirchheim unter Teck | www.appelgroup.eu |

Bobst article number BSA1089043500

Cito SYSTEM article number BJC01050

| Cito Systems | tel.: +49 911 958 850 | Technical Specialist |

| 4Heimendorfer strasse 37 | sales@cito.de | |

| D 90571 Schwaig | www.cito.de |